In the world of industrial processes, ensuring the accuracy of gas monitoring is crucial for maintaining safety, efficiency, and compliance with environmental regulations. That's where in situ gas analyzer come into play. These advanced tools are designed to provide reliable real-time data by measuring gas concentrations directly within the process environment. By doing so, they eliminate the need for sample extraction and potential errors associated with external analysis. This capability makes them indispensable for industries that require precise gas measurements, such as chemical manufacturing, power generation, and environmental monitoring, where even small deviations can have significant impacts on operations and safety.

Table of content

How In Situ Gas Analyzers Provide Reliable Real-Time Data

Benefits of Continuous Gas Monitoring with In Situ Gas Analyzers

Best Practices for Installing In Situ Gas Analyzers in Industrial Facilities

The Role of In Situ Gas Analyzers in Ensuring Regulatory Compliance

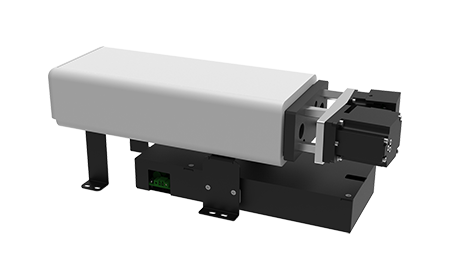

In situ gas analyzers are engineered to deliver accurate and immediate data on gas concentrations directly within the process stream. Unlike extractive systems, which require gas samples to be taken out of the process and analyzed separately, in situ gas analyzers measure gases directly where they occur. This method eliminates potential errors and delays associated with sample transport and conditioning. Tunable diode laser gas analyzer, a common type of in situ gas analyzer, use laser absorption spectroscopy to detect specific gas molecules with high precision. By tuning the laser to a particular wavelength that corresponds to the gas of interest, these analyzers can measure concentrations in real time, ensuring that data is always current and reflective of actual conditions.

Continuous gas monitoring with in situ gas analyzers offers several significant benefits for industrial operations. First and foremost, it enhances safety by providing immediate alerts to potentially hazardous gas levels, allowing for quick corrective actions. This real-time monitoring is especially vital in environments where gas leaks or emissions can pose substantial risks to personnel and equipment. Additionally, continuous monitoring helps optimize process efficiency by ensuring that gas concentrations remain within desired parameters. This optimization can lead to reduced operational costs and improved product quality. Furthermore, in situ gas analyzers contribute to better environmental compliance by providing accurate data for reporting and regulatory purposes, helping industries meet stringent environmental standards.

Proper installation of in situ gas analyzers is critical to ensure their accuracy and reliability. When installing these devices, it's essential to select appropriate measurement points within the process to obtain representative gas samples. Placing the analyzer in locations with stable flow and temperature conditions helps minimize measurement errors. Another best practice is to ensure that the analyzers are installed at accessible locations for routine maintenance and calibration. Regular calibration against known standards is necessary to maintain the accuracy of the measurements. Additionally, protecting the analyzers from harsh environmental conditions, such as extreme temperatures or corrosive gases, can extend their lifespan and improve performance. Integrating the analyzers into a centralized monitoring system allows for automated data collection and real-time analysis, further enhancing their utility.

In situ gas analyzers play a pivotal role in helping industries achieve and maintain regulatory compliance. Environmental regulations often mandate continuous monitoring of gas emissions to ensure that they do not exceed allowable limits. In situ gas analyzers provide the precise and continuous data required to demonstrate compliance with these regulations. For example, industries subject to Clean Air Act requirements in the United States must monitor specific pollutants and report their emissions data regularly. In situ gas analyzers can measure these pollutants accurately, providing the necessary documentation to regulatory agencies. Furthermore, these analyzers support proactive compliance strategies by enabling early detection of potential violations, allowing industries to take corrective actions before non-compliance occurs.

In conclusion, in situ gas analyzers are essential tools for accurate and continuous gas monitoring in industrial processes. Their ability to provide real-time data enhances safety, optimizes operations, and supports regulatory compliance. By following best practices for installation and maintenance, industries can maximize the benefits of these advanced analyzers. For those looking to integrate in situ gas analyzers into their operations, exploring options like tunable diode laser gas analyzers can be a valuable step toward achieving precise and reliable gas measurements.