Email

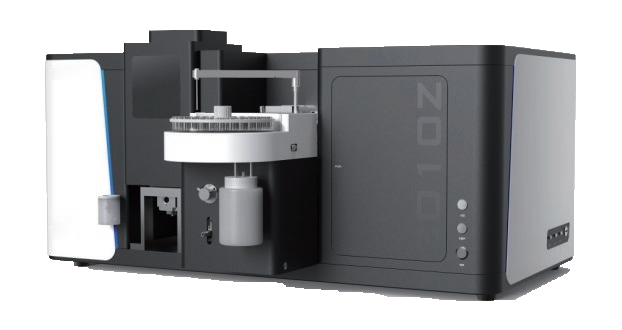

EmailThe 2010Z Series is an innovative, high-performance elemental analyzer that integrates polarized Zeeman background correction technology with a dual-detector system and multiple patented features. Its intelligent dual-mode design allows seamless switching between flame atomization and graphite furnace atomization, enabling precise analysis of complex samples. The instrument features a suspended optical system and dual-beam configuration for enhanced measurement stability. Its smart software and hardware architecture ensures safe, user-friendly operation, making it ideal for applications in scientific research, environmental protection, biomedical, and chemical industries.

Features

8-Lamp Turret with Encoding: Automatically identifies and switches element lamps with synchronized preheating, improving efficiency and reducing time costs.

Dual-Detector Synchronous Acquisition: Simultaneously captures sample and reference beam signals to eliminate time drift errors and reduce baseline noise, significantly enhancing background correction accuracy.

Polarized Zeeman Background Correction: Offers full-wavelength coverage for precise background subtraction across all elements, overcoming limitations of traditional D₂ lamp correction—especially for sodium and potassium.

Multimedia Graphite Furnace Visualization: Displays real-time sample behavior during drying, ashing, and atomization inside the graphite tube, simplifying maintenance.

PID-Controlled Optical Heating: Ensures high sensitivity and repeatability.

Independent Gas Flow Control: Separates internal and external gas regulation to protect the graphite tube and extend its lifespan while improving analytical sensitivity.

Comprehensive Safety Monitoring: Includes water pressure, gas pressure, graphite tube status, current monitoring, acetylene leakage detection, flame monitoring, and emergency power-off protection via an integrated gas circuit design.

Automated Sample Handling: Supports automatic preparation of standard solutions, sample pre-concentration, dilution, matrix modifier addition, and cleaning under graphite furnace control.

Applications

Environmental Monitoring

Food Safety

Biomedical Analysis

Agricultural Environmental Protection

Industrial Production

Specifications

| Optical System | Optical Path | Dual-beam system |

| Wavelength Range | (180-850) nm | |

| Monochromator | Czerny–Turner type | |

| Grating Lines | 2400 lines/mm | |

| Slit Widths | 0.1, 0.2, 0.4, and 1.0 mm (automatically switchable) | |

| Resolution | ≤0.2nm | |

| Wavelength Accuracy | ≤0.15nm | |

Spectral Bandwidth Deviation | Within 0.02nm | |

| Baseline Drift | Within 0.008Abs (15min) | |

| Lamp Mount | 8-lamp turret | |

| Background Correction Modes | Constant Magnetic Field Zeeman Background Correction | |

| Background Correction Capability | Greater than 60* | |

| Magnetic Flux Density | 1.0T | |

| Graphite Furnace Automization System | Operating Temperature | Room temperature to 3000?C |

Maximum Heating Rate | ≥3000℃/s | |

| Temperature Control Accuracy | ≤1% | |

| Heating Method | Longitudinal heating | |

| Heating Modes | Ramp heating, step heating, and optical-controlled heating | |

| Characteristic Mass | Cd≤1*10-12g, Cu≤1*10-11g | |

| Repeatability | RSD≤3% (Cu, Cd) | |

Flame Atomization System | Measurement Method | Air–acetylene flame technique |

| Burner Head | All-titanium construction | |

| Atomization Chamber | Explosion-proof and corrosion-resistant | |

| Nebulizer | High-efficiency glass nebulizer | |

| Characteristic Concentration | 0.015mg.L-1(1% Cu) | |

| Detection Limit | 0.002mg.L-1(Cu) | |

| Repeatability | RSD≤1.0% | |

| Graphite Furnace Autosampler | Sample Tray Capacity | 60 sample cups and 6 reagent cups |

| Cup Volume | Sample cups: 2 mL; Reagent cups: 20 mL | |

| Injection Volume | (5-1000) ul | |

| Repeat Injection Cycles | Configurable from 1 to 99 times |