Email

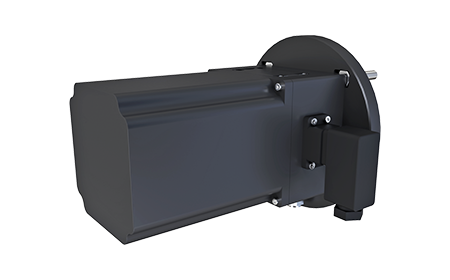

EmailMS-1000 Dust Monitor is a self-developed online dust analysis product based on back scattering principle of laser. The core components are all imported. The product is mainly used for continuous monitoring of particulate matter concentration, realizing continuous dust detection for single point or multiple points. It can also be matched with CEMS to provide real-time dust data.

Features

Support on-site zeroing and span calibration

Auto gain control and temperature compensation

Small and compact structure, easy for installation and disassembly

Eliminate interference of stray light in the background

Applications

Applied in dust emission detection, detection and control in desulphurization & dust removal engineering of flue gas in power generating boiler, industrial kiln and industrial boiler of thermal power plant, steelworks, cement production factory, ceramics factory and waste incineration plant, etc.

Specifications

Flue diameter: 0.5m~15m (customizable)

Power: <3W

Range: 0~500mg/m3, 0~10g/m3 (customizable)

Indication error: 20%

Span drift: ±2%F.S.

IP grade: IP65

Flue gas temperature:<300℃ (higher temperature can be customized)

Human-computer interaction: upper computer software, bluetooth is optional

Analog output: 1x4-20mA, max load of 800Ω

Communication interface: RS485, 2xrelay output

Working temperature: -20℃~45℃